Favorites

Glazed Brick

To create the unmistakable look of Glazed brick, a glaze is applied to the outer surface of extruded clay and carefully fired, allowing an unlimited long-lasting color range and variation of textures from glass smooth to speckled and rough.

You May Also Be Interested In

We Can Help With Your Next Project

Discover the latest + greatest in design trends, industry news & pro tips from pros.

For all of your project needs, you’ll find everything you need at a Supply Center.

Let Us Know How We Can Help!

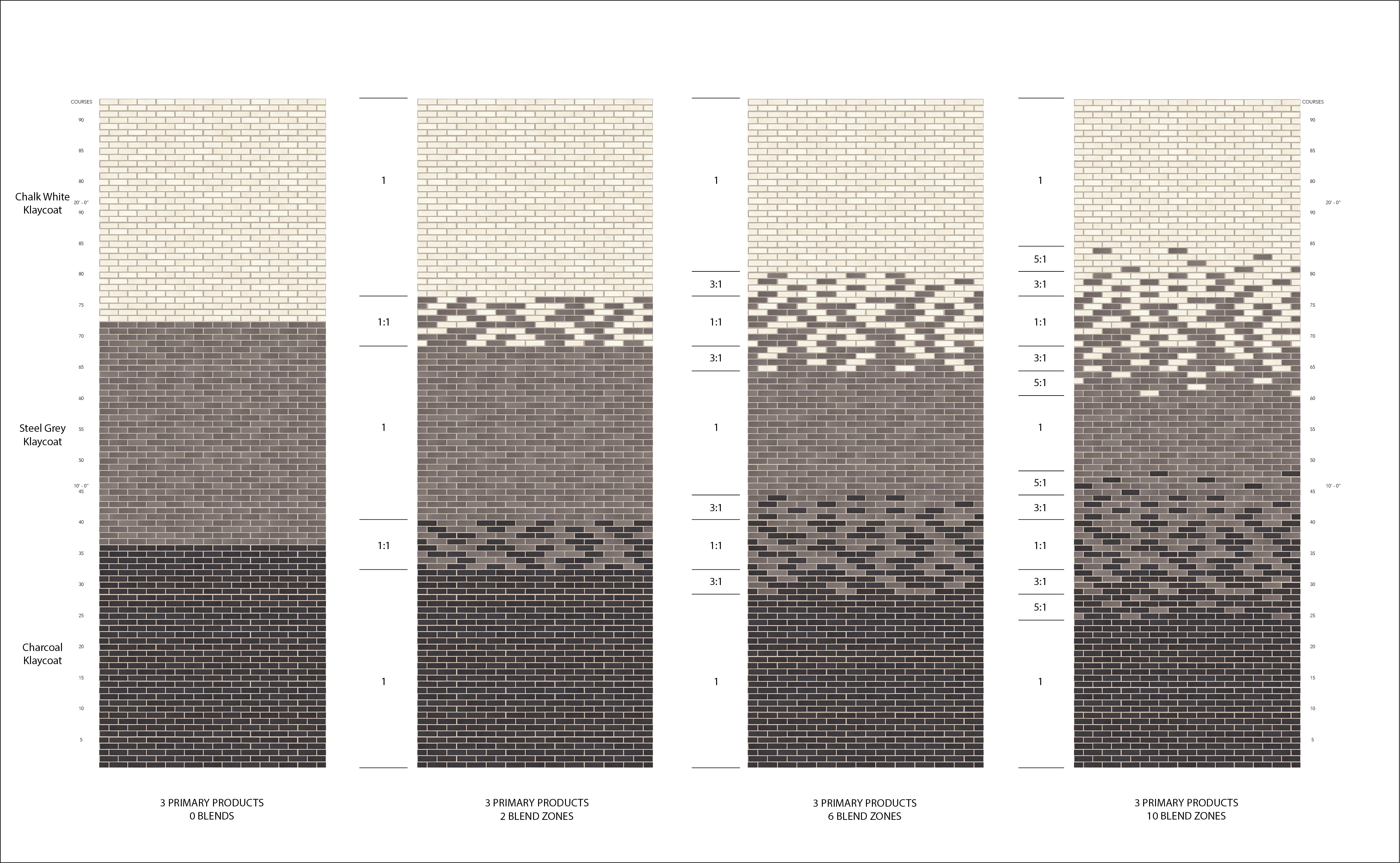

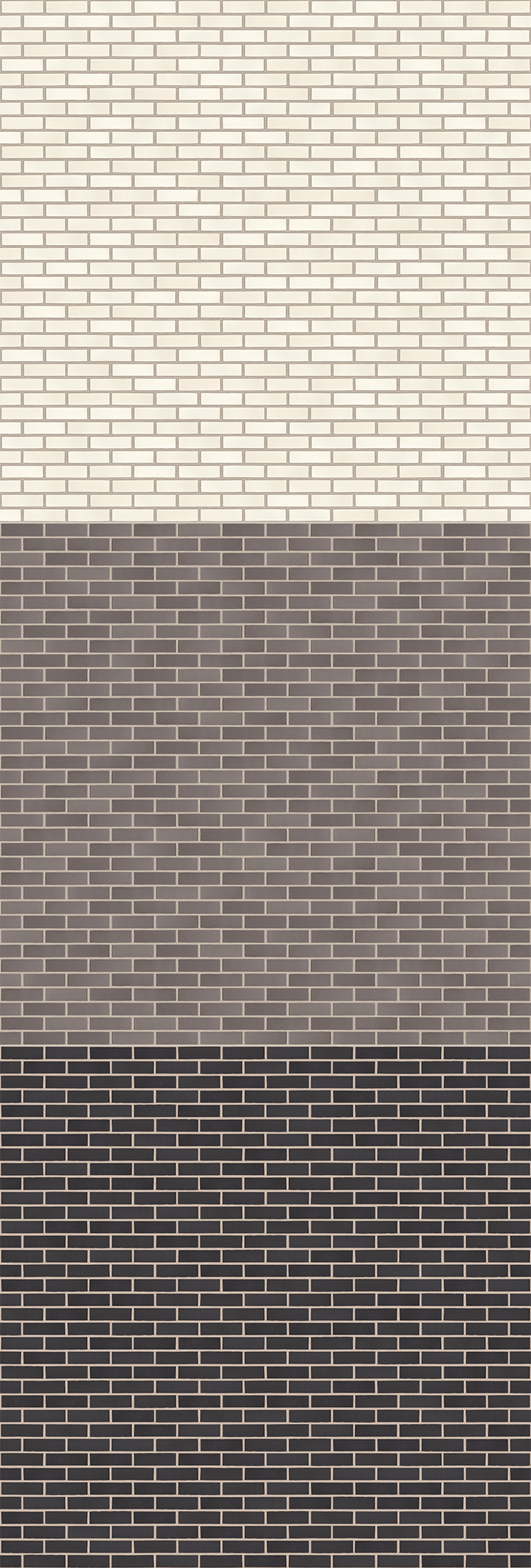

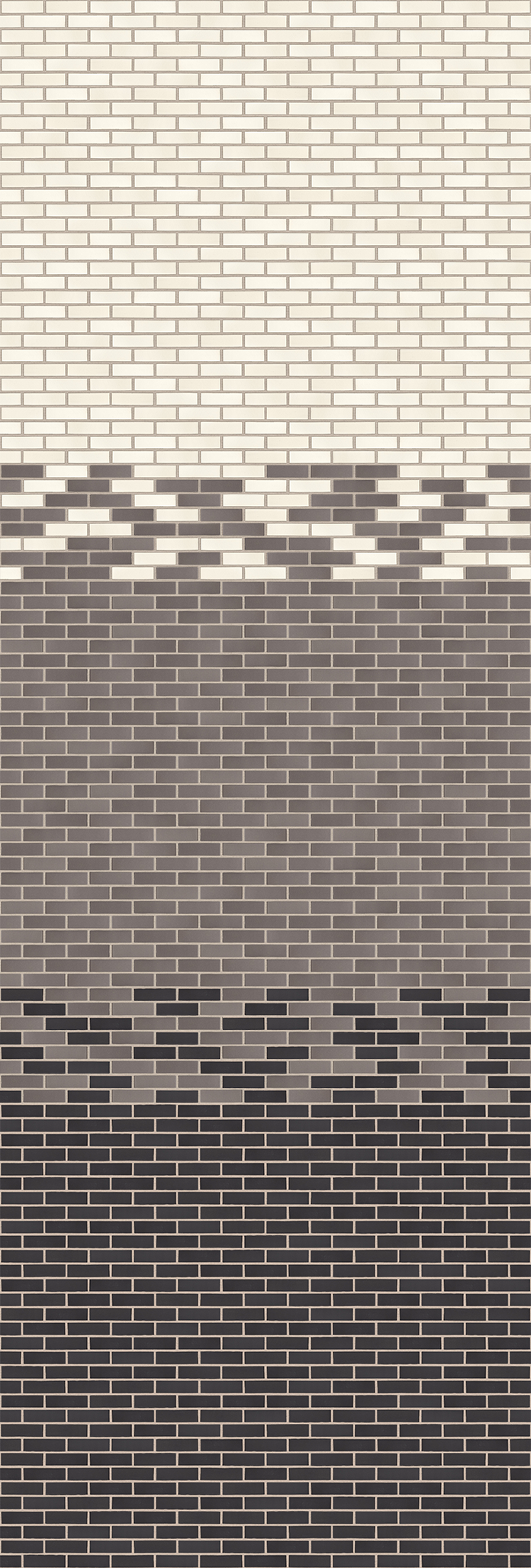

Klaycoat Brick

When you build with Glen-Gery Klaycoat®, color is more than just a finishing touch. It’s a focal point that takes any project from “okay” to “outstanding.” That’s inevitable when you have the opportunity to customize the color of your project in an unexpected way to meet any ask and exceed every expectation.

You May Also Be Interested In

We Can Help With Your Next Project

Discover the latest + greatest in design trends, industry news & pro tips from pros.

For all of your project needs, you’ll find everything you need at a Supply Center.

Let Us Know How We Can Help!

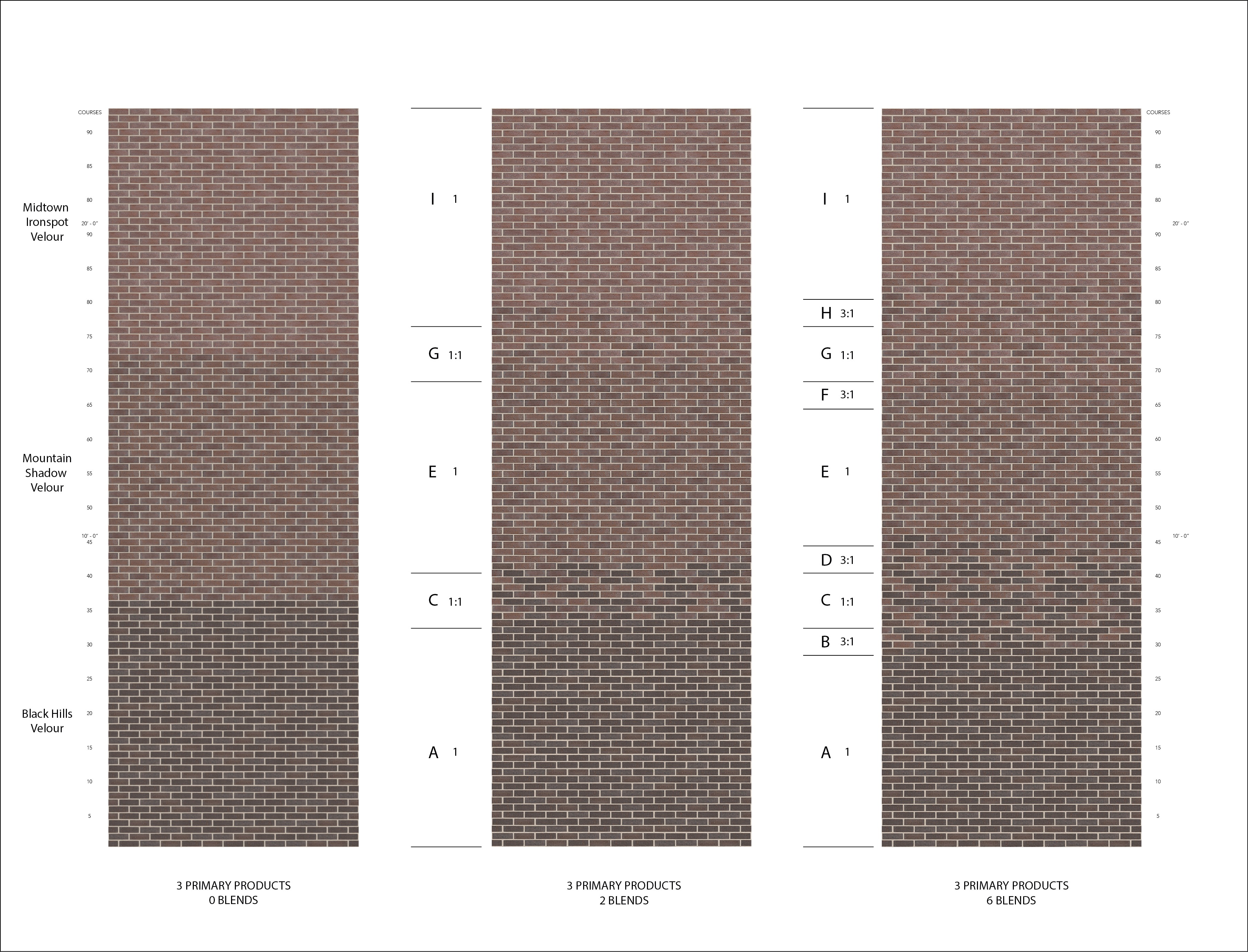

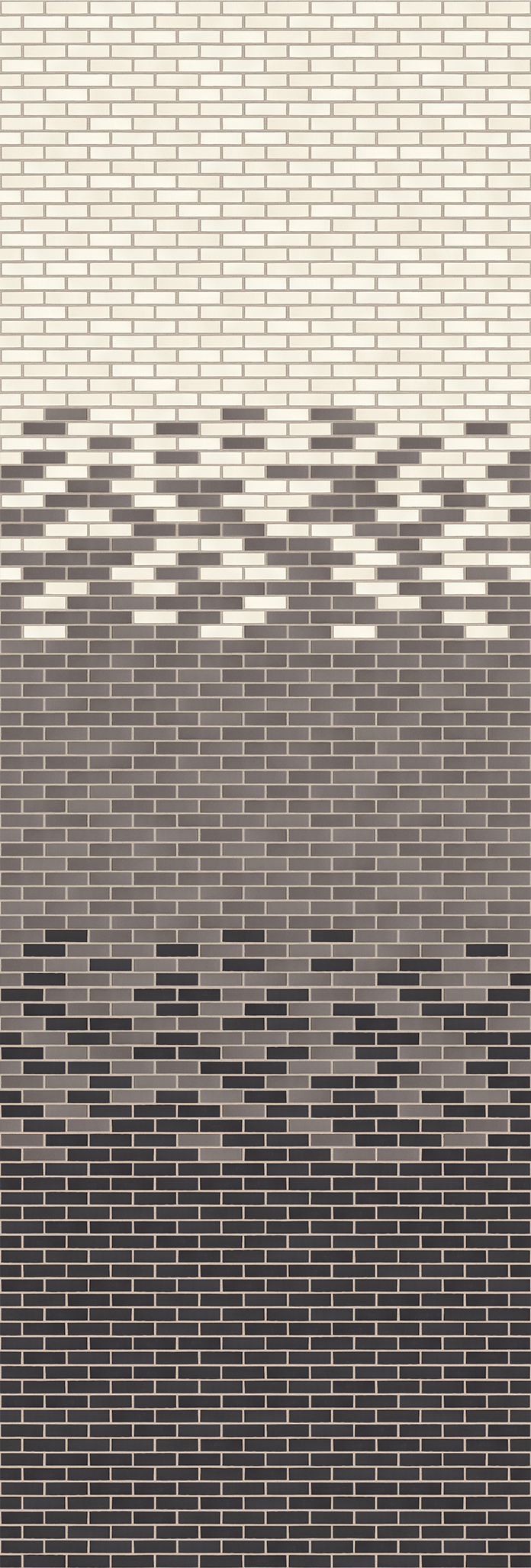

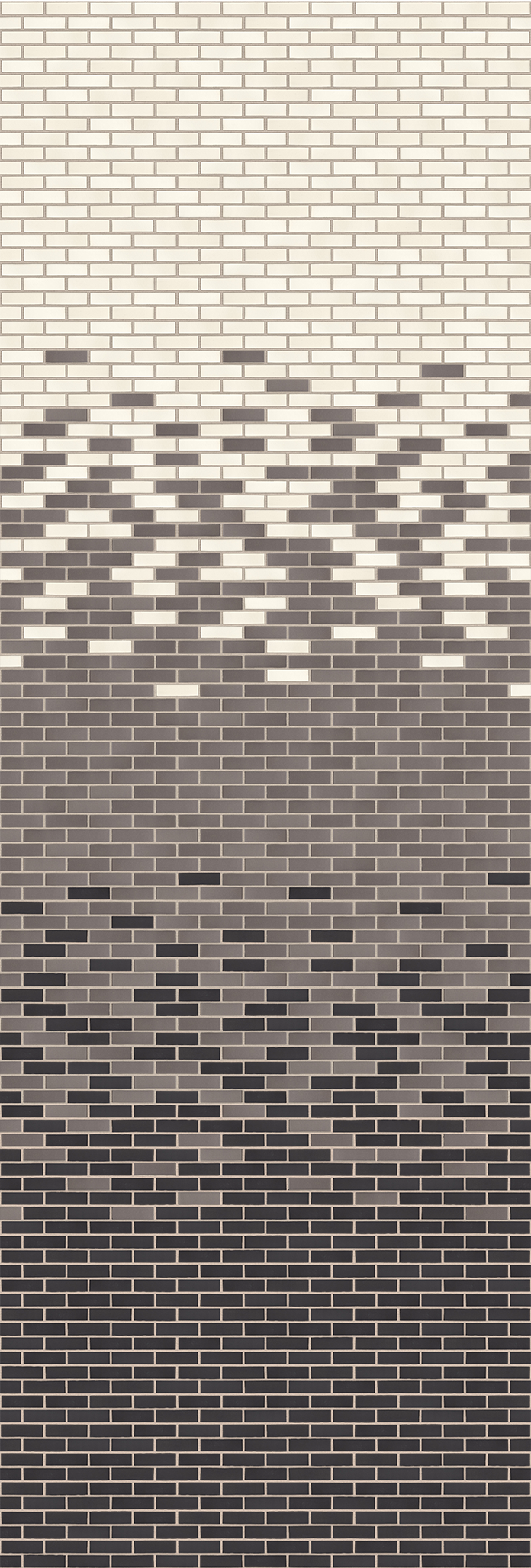

Gradient Brick Blends

Using Gradient Brick Blends in an Architectural Project

Brickwork is a timeless element in architecture that can create a distinctive character for any building. Incorporating gradient brick blends in an architectural project can add a unique aesthetic element. Gradation can be achieved through blending bricks of different colors, textures, or sizes. This technique can create a striking visual effect, such as a smooth transition from one color to another, or a subtle variation within a single color family.

In addition to aesthetic benefits, gradient brick blends can enhance the functionality of a building. For instance, blending darker bricks near the base of a building can provide better durability, while lighter shades at the top can reflect more sunlight and reduce heat absorption.

When laying the bricks, it's important to follow the manufacturer's instructions for the specific blend. Typically, these bricks are laid in a random pattern to achieve a natural look. The gradual color transition creates a sense of depth and texture, adding dimension to the project.

Using gradient brick blends can elevate any design, creating a unique and cohesive look. Whether you're designing a single story or a multi-level structure, consider incorporating this technique to add a touch of artistry and sophistication to your project.

|

|

|

|

You May Also Be Interested In

We Can Help With Your Next Project

Discover the latest + greatest in design trends, industry news & pro tips from pros.

For all of your project needs, you’ll find everything you need at a Supply Center.

Let Us Know How We Can Help!

Design Vault Ep. 28 55 Brighton with Rob Clocker

ABOUT THE ARCHITECT:

|

Rob joined Hacin in 2014 and assumed the role of Vice President and Managing Principal in 2023, bringing 30 years of experience in award-winning renovation and new construction projects. During his time at Hacin, he has completed The Whitney Hotel in Beacon Hill, the IIDA New England award-winning IDEO Cambridge, Public Garden Townhouse, and Chestnut Townhouse 2. He is also managing the ongoing mixed-use development at 41 Berkeley Street. Previously a Senior Associate at Perkins+Will in San Francisco, Rob led the revitalization of a 26-story Art Deco office tower, the transformation of a historic hospital to apartments in the Presidio of San Francisco, and the P/A award-winning design for the Calexico Land Port of Entry. As an advocate for stewardship of the built environment, he has spoken publicly on adaptive re-use and sustainable design. Rob is a registered architect, LEED Accredited Professional, and member of the Ipswich Zoning Board of Appeals. He holds a Master of Architecture degree from MIT and an undergraduate degree in Architecture from the University of Virginia. In his spare time, Rob enjoys carpentry, travel and photography. |

|---|

ABOUT THE PROJECT:

55 Brighton, a mixed-use commercial project located in the Allston, marks the completion of Packard Crossing, a multi-phase residential development from the Hamilton Company which provides new-build housing options in a densely populated area of the city. Completed in the spring of 2023, this project transforms a once-underutilized site that previously housed an Auto Zone and parking lots into a vibrant and sustainable addition to the community. Spanning nearly 100,000 square feet of finished space, with an additional 70,000 square feet allocated to structured parking, 55 Brighton seamlessly integrates with the surrounding context while addressing the community’s needs.

The project’s architectural concept embraces the reinterpretation of the rhythms and scale of the surrounding block while paying homage to the area's automotive heritage. The façade, with its distinctive fanned design, draws nostalgic inspiration from the winged tails of iconic 1950s automobiles, prompted by the adjacent historic Packard manufacturing facility. The brick detailing, meticulously designed to tie into the fabric of the neighborhood, adds a touch of warmth and familiarity while metal paneling on the top floor creates a dynamic visual contrast to further enhance the depth and character of the building's exterior. The façade design provides different visual experiences depending on the direction of approach along Brighton Avenue.

From the project's inception in 2015, the design team aimed to create a through-block connection, linking 55 Brighton with 83 Gardner, the initial phase of the development (completed by Hacin in 2020). Working in collaboration with Ground, Inc., the team created a pedestrian link through the block that promotes walkability and enhances the area's overall connectivity. By reinforcing the primary street edge with active retail, 55 Brighton contributes to the neighborhood’s bustling environment; the inclusion of 78 rental units contributes much-needed housing, particularly for the area’s large population of college students.

The Packard Crossing complex embraces sustainable design strategies and materials such as low-flow fixtures, solar panels, and ground water recharge, and 55 Brighton has targeted LEED Gold certification. The project's commitment to sustainability is further emphasized by the inclusion of newly planted trees, leaving the site with far more green space than previously existed. By replacing surface lots with 175 covered spaces, the project addresses the parking needs of the community and offers a visually appealing solution to the needs of future development opportunities.

Mirroring the architectural concept, the interior design of 55 Brighton was also carefully crafted to reflect vibrant streetscape patterns and automotive shapes and forms. The team selected materials and finishes that embody the project's goals and create a harmonious blend of functionality and aesthetics. The inclusion of Packard-inspired details honors the area's history and adds a unique touch to the living areas, grounding the space with its specific context and past.

55 Brighton

Featuring Oyster Grey Wirecut

See MoreTRANSCRIPT

00;00;00;02 - 00;00;05;13

Doug Pat (DP)

Let's go inside the vault. The design vault.

00;00;05;15 - 00;00;36;09

Rob Clocker (RC)

This collection of blocks has several landscaped alleys to help connect people from front to back. So having pedestrian connections through the block were an important part of the planning of the project. The project itself is a fairly typical four and five stories of housing overtop of a parking podium kind of housing project, which you see all over the country.

But we had hoped to blend it in with the neighborhood, of course, and so had to find ways to tie it together.

00;00;36;11 - 00;03;34;04

DP

This is my guest, Rob Clocker. I'll share more about him shortly in this episode from The Design Vault. We highlight Rob's project, 55 Brighton Avenue in Boston, Massachusetts. 55 Brighton is a mixed use commercial project that marks the completion of the Packard Crossing housing development in the Allston neighborhood of Boston. The building transforms a once underutilized site that previously housed retail and parking lots.

Transform the site into a vibrant and sustainable addition to the community. The architecture pays homage to the area's manufacturing heritage. The design concept reflects the vibrant streetscape patterns and automotive detailing. The building contains nearly 100,000 square feet of finished space, with an additional 70,000 square feet allocated to structured parking. The project reinterprets the rhythms and scale of the surrounding block, while paying homage to the area's automotive heritage.

The facade, with its distinctive folded fan like design, draws nostalgic inspiration from the wing tails of iconic 1950s automobiles. This design move prompted by the adjacent historic Packard Manufacturing facility. The brick details tie into the fabric of the neighborhood and add warmth and familiarity. While metal panels at the top floor create a dynamic visual contrast to the brick facade.

The complex embraces sustainable design strategies and materials such as low flow fixtures, solar panels and groundwater recharge. Hi, I'm Doug Pat and this is Design Vault. Hi. Rob Clocker holds a master of architecture degree from MIT and an undergraduate degree in architecture from the University of Virginia. Previously a senior associate at Perkins and Will in San Francisco. He's now a vice president and managing principal at Hacin, an award winning interdisciplinary architecture and design firm in Boston.

With 30 years of experience and award winning renovation and new construction projects. Rob's worked on buildings from office towers to land ports of entry. During his time in Hacin, he completed the Whitney Hotel in Beacon Hill, The IIDA New England award winning ideas. Cambridge Public Garden Townhouse and 55 Brighton Avenue. He's also managing the ongoing mixed use development at 41 Berkeley Street.

As an advocate for stewardship of the built environment, he's spoken on adaptive reuse and sustainable design. Rob is a registered architect, LEED accredited professional and member of the Ipswich Zoning Board of Appeals. So welcome, Rob. It's nice to have you with us today. So tell us a little bit about Hacin Architecture and Design firm in Boston. So where are you guys located in the city?

What's the size of the firm? How long have you been around and what type of architectural and design work do you do?

00;03;34;07 - 00;04;42;16

RC

Thank you, Doug. It's really great to be here with you. Hacin is, as you mentioned, an interdisciplinary design firm where 35 people we take the word interdisciplinary pretty seriously. We have architects, we have interior designers, we have visual and graphic designers. And we think of that because as a concept driven firm, we like to take the idea of the design all the way from the outside of the architecture to the inside and throughout to the entire experience.

The firm is located in the south end of Boston, which is one of Boston's many historic neighborhoods. It was founded 30 years ago by our founding principal. David Hacin started at his dining room table and gradually built up to the 35 people we have today. And all that time has been in the South end. So in some sense, we're a neighborhood architecture firm.

In another sense, we think we've learned how to build buildings and do design in places that people love in ways that they recognize. We like to joke that the buildings we build are ones we ourselves are going to have to live with ten, 20, 30 years from now.

00;04;42;19 - 00;04;47;03

DP

So you were at Perkins and well, for a little while and then ultimately found Hacin.

00;04;47;05 - 00;05;36;12

RC

It's a little bit of a convoluted story but yes, those are the facts. My career trajectory had me moving across the country four times to California and back to Boston, and I did each of those moves twice. But the last time when I was in California, I worked with Perkins and Will, and that experience was quite formative in terms of some of the things we may be talking about today because we were an outgrowth of another local firm in San Francisco, which did a lot of adaptive reuse work.

And in that role, I was able to learn surprisingly quite a bit about Brick, even though we were in San Francisco, where you don't think of that as a building material. And there's quite a bit of historic architecture out there, as you might imagine. So learning to work in that context set the stage for some of the projects I do today.

00;05;36;15 - 00;05;47;25

DP

So you've been Hacin how seen relative to all of the other things that you've done in the practice of architecture?

00;05;47;27 - 00;06;31;12

RC

My current role, which is relatively new one, starting as of last year, I'm managing principal of the firm, our founding principal, after 30 years, and a lot of growth, decided that it would be a good idea to get a new batch of principals. So we have five of us now, in addition to David Hacin and as the managing principal.

My job, of course, is to try to help us stay focused on the business side of the practice, which, as you may know, as an architect, isn't the most fun part. However, it does matter tremendously, and I like to think of it as fundamental to helping us do the great design work we do, because ultimately, if we don't do good business work, we're not going to be able to do great design work.

00;06;31;15 - 00;06;37;25

DP

So true. So let's dig in here and talk a little bit about the project. How did you guys get the work?

00;06;37;27 - 00;07;38;12

RC

Sure. As with many projects in Boston, it's a very much relationship based city. This owner, the Hamilton Company, is old company and one of the largest landlords in Boston founded by Harold Brown. And in that very neighborhood that the project exists, we developed a relationship with them and they reached out to us specifically because they understood that we knew how to fit new buildings into existing neighborhoods, as well as to help owners like this company navigate the sometimes complex approvals process, which you find in many East Coast cities.

And Boston is certainly one that has its web of interested parties in every project. The Hamilton Company, however, because of being a longstanding company, has very good relationships with the neighborhood, with neighborhood association owns as well as the city. And so it was a good partnership in coming up with a design that would appeal to a lot of different factions.

00;07;38;14 - 00;07;45;19

DP

So tell us a little bit about the site, the history of the location, what was there and what you guys ultimately built.

00;07;45;21 - 00;08;45;14

RC

This site, which is an area called Packard's Crossing, which is so named because originally it was a location of a Packard car manufacturing plant, is a mixed use site. It has a lot of Boston rowhouses that go further down the street from our location. But the location of the particular project did have some of those more industrial uses.

And in the more recent years it had been transformed somewhat into parking lots and some low rise retail in ways that weren't necessarily sensitive to the neighborhood. As it happens, one of those buildings was the owners primary headquarters, and so it was a very near and dear to them that they do something on this site, which was good.

And because this was their headquarters, they owned numerous properties that adjoins. So they undertook a master planning process with us to think about how they could not only develop a 55 Brighton but 83 Gardiner, which is nearby and tie it all together in a sensitive way.

00;08;45;17 - 00;08;51;19

DP

So what was the ultimate scope and what were the programmatic requirements for the project? The building you designed.

00;08;51;21 - 00;09;52;29

RC

The program for 55 Brighton, on the face of it, is a fairly straightforward program. It's 77 rental units, a housing and parking garage for that housing as well as retail that would line Brighton Avenue, which is a mixed use street. The more interesting or maybe effective overlay of that program is that this collection of blocks has several landscaped alleys to help connect people from front to back.

The streets in this neighborhood aren't necessarily as frequent as some city streets are. And so having pedestrian connections through the block were an important part of the planning of the project, as well as part of the approvals for the project. And the project itself is a fairly typical four and five stories of housing overtop of a parking podium kind of housing project, which you see all over the country.

But we had hoped to blend it in with the neighborhood, of course, and so had to find ways to tie it together.

00;09;53;01 - 00;10;20;18

DP

Yeah, it's an interesting building. So you guys had to do a bunch of things with the architect. Sure. You used a lot of masonry out there, various colors, but the brick patterning and specifically stylistically the building facade as it sort of peels away in a number of locations. Very interesting. So the building's contemporary, particularly the cantilevered folding panels, and yet you utilize brick and various traditional patterns and colors.

So tell us a little bit about that.

00;10;20;21 - 00;12;26;05

RC

Sure. Our approach to the design of the facade, especially on Brighton Avenue, was the kind we take to many of our projects, which is to look carefully at the context. We look at not only what's built today, but what was built in the neighborhood previously and of course, like many of these traditional neighborhoods, there's a strong rhythm of bays and of brick along the street, which on one hand we wanted to pick up some kind of rhythm, but on the other hand, we certainly didn't want to just mimic it.

That's always the challenge we have as designers is how do we build something for today in a neighborhood from yesterday? So what we chose to do in this case, as you mentioned, is we peel the brick facade back in a regular rhythm of bays, which echoes those bays further down the street. But we do it in a way that isn't just your traditional symmetrical bay.

It lifts the facade apart in a sense. So when you're looking at it from one direction, you see a rhythm of brick bays. When you look at it from the other direction, it looks like a number of vertical metal turrets that are more reflective of what you see beyond because in that direction you're looking towards downtown, where you see a lot of the towers of downtown Boston.

So that was an important design aspect as well that you had a different experience of this building from one direction than you do from the other. And then one other aspect of that design choice has to do with how brick is used today. We no longer build load bearing brick walls. There's a lot of reasons for that, as much as we love them, but there are many, many load bearing brick walls in Boston.

So when we peel these elements back, we're just using face brick cavity wall construction like you see on all contemporary construction. But we wrapped it around, so it's the thickness of a load bearing wall, but you can still see that it's suspended in there. It's a little bit of a tongue in cheek acknowledgment of it's both symbolic of a load bearing material, but also it's being used in a way that's contemporary as a way to clad the building and give it a sense of identity.

00;12;26;08 - 00;12;37;26

DP

So let's back up just for a second. I always like to ask the architects about the project restrictions they had in regard to zoning or historical requirements. Could you talk a little bit about that?

00;12;37;28 - 00;12;45;19

RC

This project, like everywhere in Boston, as I mentioned, we have a robust approvals process for any larger projects.

00;12;45;19 - 00;12;50;06

DP

I like the word robust, it's very respectful.

00;12;50;13 - 00;13;49;06

RC

All the intentions are good. Sometimes it can become complex. Of course, this project is larger than would have normally been allowed by the underlying zoning, so it went through this process to approve a larger building and part of those approvals then have a lot to do with review of the design to make sure that the design is going to mitigate the scale of the building fit into the neighborhood in ways that we hope we've been able to be successful here, and that also there are elements to the design which contribute to the neighborhood, which gets back to some of those connections in the landscaping that I mentioned.

And as it happens on top of the rear of the building on one level, up on the parking is an extensively landscaped courtyard which is made for the residents of the building. So to this approval, we of course, had to meet with neighborhood groups. We had to go through numerous public hearings and we think we reached a place where all parties felt like there was a good compromise with this building.

00;13;49;08 - 00;13;51;14

DP

So was there a historical review.

00;13;51;20 - 00;14;02;26

RC

In this particular neighborhood? Interestingly enough, there was not a historic district review. This piece of Boston, although it has a lot of buildings from long ago, is not a designated landmark district.

00;14;02;28 - 00;14;27;09

DP

Interesting. Yeah, I thought the notion of showing this facade as it peels away as a thick masonry wall, this kind of tongue in cheek reference to historic architecture is really interesting. A great idea. Tell us a little bit about the building and plan. It looks like a giant rectangle, and yet you've done an awful lot with the facade and the undulations in the forms.

00;14;27;11 - 00;16;39;13

RC

That's one simple thing about the building is that the site is a rectangle, which we don't get a lot of those in Boston. So we were excited about that. But the housing portion component is an L-shape because as you know, with multifamily housing, there's a dimension which plays itself out really well. The rectangle of the footprint of the building has to do with the parking.

So the front of that is lined with retail on the building lobby. And then above that is the two lengths of the L-shaped housing. What we did with that then is to articulate those different volumes. That's also where we turn to the brick patterning to identify the different areas of the building. And we had to do this though, within some constraints of course, because this is a rental building and the owners wanted to keep the housing reasonably affordable.

So all of the brick we use is actually just standard modular brick, which means it's the kind of brick that we love because it's easy to lay out. It creates an eight inch by eight inch grid on the building and to be creative with modular brick, we had to do things like turn the brick on its side, create soldier courses and find ways to push the brick inward and outwards to create shadow lines.

And one of the aspects of these fins on the front of the building that we've been talking about is that they actually curve outward from the main facade. But we wanted to achieve this curve without buying any special bricks. And when the contractors did their mock up and brought it out in the sun, everybody to our horror, recognized that it was creating all kinds of jagged shadows because the bricks were rectangular and they were trying to create a curve in order to help them with that.

We actually went back to our drawings. We laid out the coursing of those brick courses and created them some full sized brick causing diagrams, which the Masons then used. They relayed out the mockups and it came out looking smooth. And this was one of those cases where what we love about Brick is it depends so much on the Masons and their desire and skill to make things work.

And that back and forth really, I think made the building much better.

00;16;39;16 - 00;17;04;29

DP

So let's start with the parameters for building materials. When you guys got rolling, did you just decide, Well, Boston's got a lot of bricks, so that's what we're going to use for the majority of the building. And then talk a little bit more about some of these coursing tapes that you use, because I did see some soldier coursing.

I saw some regular type of courses. And then, of course, there are all kinds of strategies to create shadow lines in the facade underneath the windows, etc..

00;17;05;01 - 00;18;17;23

RC

Yeah, the decision to use brick, as you say, dug was a pretty foregone conclusion. We were working in a block where all of the existing buildings, the historic buildings were brick, and it's the kind of material that really helps bring identity to the building in a way that people feel like fits with Boston. This was an idea that sometimes we fight as designers, we think we want to do something new in this city that's all made out of bricks.

But I think over time we've come to recognize that the fact of Brick in Boston is one that's time tested. It's one that brings identity to the place. And so we accepted it fairly quickly and then set out to figure out, well, how do we create different proportions, different forms, and articulate the building with these bricks as well as bring different colors to it.

So it's not all just red brick. We did use a much darker brick for the base of the building, which helps ground the building helps those bays feel like they're floating up above. And then in the courtyard we use some yellow brick, which is not what you see from the street. It gives you some variation for the expression of the building and also brightens up that space.

00;18;17;25 - 00;18;24;20

DP

Could you tell us a little bit more about the coursing types and the strategies to create shadow lines in the facade?

00;18;24;23 - 00;19;10;10

RC

Yes, we were constrained to using just regular shaped bricks. One of the coursing techniques we used was to help with the rhythm of the windows of the building. With housing, you get repetitive windows because we want to use the same kind of windows and we have repetitive apartment units. However, we wanted to create some different scale to those windows, and we use this by creating brick panels which frame some of the windows and help the windows appear to create larger patterns on the facade.

And in these brick patterns, we simply stacked the bricks and then pushed every other brick inward by about an inch, which created this nice textured shadow line, which gave it a little bit of depth similar to the depth the window had. That was one of the techniques we used to help give the building some life.

00;19;10;12 - 00;19;28;08

DP

So it's also interesting you guys ended up doing mock ups, which we all as architects end up seeing in the field an awful lot of times when we're using a lot of masonry or when things get complex. How did you do the drawings? The architectural drawings, were there 3D, was it BIM modeling, was it 2D?

00;19;28;10 - 00;20;38;26

RC

On this project, like many of our projects, we have both a design model and then a construction model. So early on we built the building and sketch up that lets us study forms colors fairly quickly and do variations to help dial in some of the aspects of the building which are going to be most conducive to the design as well as lets us be flexible with some of the city approvals processes when different requirements are brought up around the design development phase, though, we certainly built the same model in Revit and that becomes the actual construction model and Revit is where we really get into the brick detailing.

We don't draw every single brick, although we sometimes like our clients to think we're doing that. We use a combination of patterns on the surface of the model, which are very accurate to the brick module with certain areas where we will go in and manually layout the coursing because we know it needs to work in a certain way.

And so we do love using these tools. They really help us make sure that what we draw is what the Masons are going to be able to build.

00;20;38;28 - 00;21;01;25

DP

Yeah, I was really surprised when I was looking at the photographs, the peeling facade, if you will, these fan like projections. There was one photograph I looked at and you can actually start to see the curve the way the brick is manipulated in the facade. So it's not a hard line. I did not expect that when I saw that photograph.

That must have been really interesting to see worked out in the field.

00;21;01;27 - 00;22;01;22

RC

It was very interesting to see worked out in the field. That curve, however simple it seemed to us, was actually somewhat difficult for the Masons to achieve. They did do a mock up of that curve, which was not successful initially because when they laid out that mock up and put it in the sun, we saw immediately that the corners of the bricks were shadowing over top of each other, that they were struggling to make sure the crossing was smooth.

And so we went back to our drawings and we laid out each course a brick for them and printed a full sized drawing of that, causing to have them give that a try because we use the geometry of the curve to lay out where the corners should fall. Then when the Masons used that template and rebuilt the mockup, it actually came out quite smooth, which is the result you see today.

And we're actually kind of excited because that's a 20 degree change in plain between the face of the building and those projections, and it's achieved in two and a half courses of brick.

00;22;01;25 - 00;22;03;16

DP

My gosh, that's incredible.

00;22;03;19 - 00;22;08;04

RC

Flat bricks too. So we didn't have to buy curved bricks, which nobody likes to do.

00;22;08;06 - 00;22;16;15

DP

Did you do that by making the radius larger for that curve rather than having a smaller radius? Am I understanding that correctly?

00;22;16;17 - 00;22;37;28

RC

It was almost simpler than that. The radius didn't change. It's just which parts of the brick touched the radius needed to be adjusted because the Masons were having the corners and the flats of the bricks that were of course with each other overlapping in a way that cast shadows. And if we just moved those back, the shadows faded away.

00;22;38;04 - 00;22;44;01

DP

Very cool. So how many people were on the team working on the building over time?

00;22;44;03 - 00;23;10;16

RC

From the start of the project, we had just a couple of people. We had our project manager, Jeff Brown, as well as a couple of junior designers helping with the various models and presentations. By the time we got to CDs, there were five of us putting the drawings together and then for construction it was down back to just two of us getting through the various needs of the construction site.

00;23;10;18 - 00;23;14;23

DP

And how long was the process start to finish, including reviews.

00;23;14;25 - 00;23;42;12

RC

These kind of projects, tt's always interesting to answer that question because we've been working on this site with this owner for over ten years. This project was in the queue to it's the biggest one on the site, but it was one of the last ones we did with them. So the early ideas for it were probably seven or eight years ago.

But by the time we started the actual design, that took a little over a year and a half, then the construction took about two and a half years.

00;23;42;14 - 00;23;51;03

DP

So I love to ask architects if there was anything interesting through the design and construction process that you guys learned that was kind of new to you?

00;23;51;05 - 00;24;55;27

RC

Yeah, I think this project probably one of the more interesting and challenging but creative aspects of the project is that this client is their own developer and their own contractor. They are the ones who both financed the building and built the building, but they did hire us to design the building and of course hired the subcontractors to build the building with them.

But there were many times when you're working with a client who is building their own buildings that they are in a hurry because they figured they know what they're doing and they want to move forward and so very often we would find ourselves kind of rushing to stay, keep up with them. And what I think was an important lesson for us or something we were glad about is that we did take the time to do a really strong set of drawings during the design phase so that every time the client tried to get ahead of us, we had a good set of documents to help them not get into trouble.

That's not always the case. Sometimes clients will hurry you through the design with the thought that during construction you can figure out some more of the details.

00;24;56;00 - 00;25;00;24

DP

So the project wasn't bid out then to a contractor or it was?

00;25;00;27 - 00;25;11;02

RC

The project was not bid out to a general contractor because the general contractor was the client. However, they did bid out all of the different trades, including the masonry trades.

00;25;11;04 - 00;25;15;01

DP

So it was an extraordinarily thorough set by the time you guys were done.

00;25;15;08 - 00;25;19;17

RC

We did have a very strong set of drawings which always makes us happy and protects us.

00;25;19;19 - 00;25;32;24

DP

Makes things a little easier down the road. So, Rob, you've been an architect for a while. Based on what you know today about being an architect, do you have any words of advice for your younger self or even young architects coming down the pike?

00;25;32;27 - 00;25;56;13

RC

Sure. I think one of the pieces of advice I have learned over the career is it really matters to trust in the simplicity of design and to keep things basic. You may think, as I did as a young designer, that you need to add a lot of ideas and things like Brick are boring. But actually if you just stick with the basics, you can come up with quite an elegant solution.

00;25;56;15 - 00;26;33;06

DP

Yeah, I always find that interesting, this idea that when you have limitations or parameters, many times young people think, Well, I'm not going to be able to do anything creative inside of this notion that things should be simple or minimal in some way. And yet I think that is the key to creating things that have never been done before.

Perhaps I love this idea that when I'm given lots of restrictions, I still have to be, I still want to be creative. So I think that ties a little bit into what you just said.

00;26;33;09 - 00;26;54;11

RC

I completely agree. I think something else we find about trying to stick with the basics is very often when you're trying to tell a story and come up with a concept which other people can understand, you really have to stick to the story and stick to the basics. And so these rules were made for a reason and they're really great to flex and learn from.

00;26;54;14 - 00;27;03;24

DP

Well, Rob, thank you very much for being with us today. And thanks for your time. Where can people go to learn more about Hacin Architecture and Design and yourself?

00;27;03;26 - 00;27;21;20

RC

Thank you, Doug. It's been a great pleasure to be here today. And you can go to www.Hacin.com to learn about us or come to Boston's South End. And we're always happy to give people a tour of both our projects and a lot of the great historic architecture in Boston.

00;27;21;22 - 00;27;27;28

DP

Well, thanks again, Rob. Beautiful project. Congratulations. And we'll see you around Boston.

00;27;28;01 - 00;27;31;10

RC

Thank you, Doug.

You May Also Be Interested In

We Can Help With Your Next Project

Discover the latest + greatest in design trends, industry news & pro tips from pros.

For all of your project needs, you’ll find everything you need at a Supply Center.

Let Us Know How We Can Help!

Design Vault Ep. 29 29 Huron with Vicente Quiroga

ABOUT THE ARCHITECT:

|

Vicente is a project manager with over 10 years of experience and a diverse portfolio encompassing various building typologies, the restoration of historic structures, complex interior layouts, and both public and private work. He is currently managing the construction administration of 1 Huron—a 266,000-square-foot multifamily building with ground-floor retail and a generous package of high-end amenities located along the East River within Brooklyn’s Greenpoint neighborhood. Based on his involvement in the design of the project, Vicente has an intimate understanding of New York City's building codes and requirements related to waterfront development and building within flood zones. |

|---|

ABOUT THE PROJECT:

The building is defined by 2 13 story towers connected by a shared lobby whose step forms narrow on the higher floors. The two tower massing maximizes unobstructed views across the East River, taking advantage of its exceptional waterfront location. Due to the building's location in a flood zone, Morris Adjmi coordinated closely with consultants to provide active flood protection solutions such as deployable flood barriers, temporary stairs, flood vents and flood resistant glazing at storefronts. Located within the building's podium, many of the Huron's amenity spaces fall within the design flood elevation, including the indoor pool. Flood resistant glazing within these spaces maintains transparency. The building's glass and steel towers reflect Greenpoint's industrial heritage, while the rough brick podium is inspired by the materials and scale of surrounding warehouses. The heavily gridded facade is comprised of a window wall system featuring I-beam profiles on the pillars.

TRANSCRIPT

00;00;00;02 - 00;00;05;10

Doug Pat (DP)

Let's go inside the vault. The design vault.

00;00;05;12 - 00;00;31;14

Vincente Quiroga (VQ)

We actually decided early on that we would adopt the one story podium and also set back sooner than we actually needed to. It increases the lighting there allows for breezes that blow through. It also allows for multiple outdoor terracing to happen. So those units that aren't particularly high and don't have the same views can step out onto your terrace and see the water.

And so really maximizes the value and effectiveness and the quality of those spaces.

00;00;31;16 - 00;01;05;23

DP

This is my guest, Vicente Quiroga. I'll share more about him shortly. In this episode from the Design Vault we highlight, Vicente’s project 29 Huron in Greenpoint, Brooklyn. The Huron is a mixed use multifamily 13 story 266,000 square foot building with ground floor retail and high end amenities. In order to account for the narrow site geometry and flood zone, multiple massing schemes were studied with an objective to maximize height and floor area distribution and prioritize views.

The building is defined by 2 13 story towers connected by a shared lobby whose step forms narrow on the higher floors. The two tower massing maximizes unobstructed views across the East River, taking advantage of its exceptional waterfront location. Due to the building's location in a flood zone, Morris Adjmi coordinated closely with consultants to provide active flood protection solutions such as deployable flood barriers, temporary stairs, flood vents and flood resistant glazing at storefronts. Located within the building's podium, many of the Huron's amenity spaces fall within the design flood elevation, including the indoor pool. Flood resistant glazing within these spaces maintains transparency. The building's glass and steel towers reflect Greenpoint's industrial heritage, while the rough brick podium is inspired by the materials and scale of surrounding warehouses. The heavily gridded facade is comprised of a window wall system featuring I-beam profiles on the pillars.

Hi, I'm Doug Pat and this is Design Vault. Vicente is a registered architect and project manager at Morris Adjmi Architects in New York City. He holds a Bachelor of Arts in Architecture from New York University and a master of architecture from the City College of New York. He has a diverse portfolio encompassing various building types, such as historic renovations, interiors, hotels, art exhibition spaces, educational facilities and high end residential buildings in the Northeast, the United Kingdom and Spain.

Vicente also has a broad and unique understanding of New York City's building codes and requirements related to waterfront development and building within flood zones. He's currently managing the Construction Administration of 1 Huron on a 266,000 square foot multifamily building along the East River in Brooklyn's Greenpoint neighborhood. Prior to joining Maurice and me, Vicente worked on public restoration projects for the New York City School Construction Authority and the New York City Department of Design and Construction.

So welcome, Vincente. It's nice to have you with us today. Now, for those of you listening who have not heard our interview with Michelle Wagner from Morris Adjmi during the first season. Vicente, could you tell us a little bit about the firm? So where are you guys located? What's the size of the firm? How long has it been around and what kind of work do you do?

00;03;38;11 - 00;04;12;25

VQ

We're based in New York City, near the financial district and Wall Street. We also have a New Orleans office as well, because Morris is originally from there. So we have a broad practice, decades of experience, really working first in New York, and particularly in landmark districts and contexts as well as broadening that to sort of a national practice and also very holistic practice involving urban design, placemaking architecture, interiors, furniture and art services.

The New York office is approximately 70 people, and I think we have about 10 to 20 people in the office as well.

00;04;12;27 - 00;04;18;07

DP

So how long have you been with Morris Adjmi? How long have you been a registered architect and what do you do there?

00;04;18;10 - 00;04;58;00

VQ

So I've worked for about six years there and I've been a registered architect for 12 to 13 years in practice. Prior to that, over 15 years of experience since graduate school. So my role is project manager and flex project architect position, just really responsible for anything and everything to do with the project from client management, coordination, staffing, everything, being accountable for the project throughout the life of it.

And this one in particular has been special because, you know, in a large practice you often inherit projects or people come and go. This project for me has been involved since day zero through completion, so it's very special to me.

00;04;58;07 - 00;04;59;16

DP

And how long has it been?

00;04;59;19 - 00;05;10;24

VQ

Started in 2018, so, you know, approximately five or six years. Some of that was due to the pandemic. There is some slow down pausing during that time where it would have sort of completed a little bit faster.

00;05;10;27 - 00;05;18;03

DP

So most architects at Morris Adjmi are with one project the entire way through and are working on other jobs at the same time.

00;05;18;09 - 00;05;31;02

VQ

Everyone's multitasking. I myself have about six projects actively in different stages of a construction administration or schematic and design development as well. We like to flex our brain.

00;05;31;05 - 00;05;33;02

DP

And how do you like being a project manager?

00;05;33;09 - 00;06;04;25

VQ

It's good. It's a very challenging role because you're juggling practical logistics as schedule and staffing and the finances, but you're also deeply involved with building the client relationship and trust and working with the team to get to the milestones of the project and deliver what you're trying to do, but also take a higher view and really emphasize what are we trying to do here?

What is the objective from a practical standpoint to meet their needs of the project, But also what is the design move? What's the inspiration? What are we trying to do and maintain that throughout the life of the project, which isn't easy?

00;06;04;27 - 00;06;08;14

DP

No, it's not. And how big is the team for the Huron Project?

00;06;08;21 - 00;06;41;06

VQ

It's ebbed and flowed. At some points you have ten people during extensive documentation process. During CA, I think we have about five people. It's particularly because it has extensive interiors. We've staffed sort of an architecture team as well as an interiors team, and then they also have taken on the furnishings and art for the project. So we have over 30,000 square feet of interior amenity with pools and meeting rooms and kids rooms, as well as some outdoor activities where we also collaborated with the landscape architects. So there's a lot of things going on.

00;06;41;09 - 00;06;43;06

DP

And how did your office get the job?

00;06;43;08 - 00;06;59;03

VQ

Well, we were selected from a RFP process with the client. They had tried to develop it into a different solutions in the past and weren't very happy with those studies. So they approached us in a feasibility concept phase to sort of see what they could do as of. Right.

00;06;59;06 - 00;07;00;27

DP

And did you guys know the clients?

00;07;01;00 - 00;07;27;12

VQ

We knew them. It's really our first project with them. We've heard of them before. The client is interesting in that they have a range of experiences of multifamily and hospitality projects in their portfolio and they're also client. That's up for a challenge. You know, the site dimensionally was challenged, the site conditions in terms of remediation of the industrial sites and also its waterfront access, those are all challenges to the design that they were up for.

00;07;27;14 - 00;07;33;25

DP

So tell us a little bit about the history of the location of the site. What was going on there before you guys got there?

00;07;33;28 - 00;08;39;17

VQ

The history of the site, you know, it's a long, narrow site. Our building massing is 100 feet in the north south direction. It's over 500 feet in the east west direction. So it's very distended and lengthened and narrowed. The original site was a one story warehouse, which was kind of the context of the neighborhood. I lived in that neighborhood many years ago, and that was the context.

The context is changing primarily because in a sort of Bloomberg era, there was a zoning plan, but then the 2008 crisis stalled those plans, and it took a while for that increased zoning and development to come to fruition. And so we were part of that increased zoning for the site. In terms of the massing, we wanted to take a sense of the character that was there and honor that.

Not all the projects that we see built really take that into account. And we were thinking, what is the context now and what was the context in the past? So we really thought about selecting a one story podium and selecting Brick as the foundation for that, and also being practical about the openings and where they're located.

00;08;39;20 - 00;08;45;24

DP

Right. So that's a good segue to my next question. So what was the scope and the programmatic requirements for the project?

00;08;45;27 - 00;09;00;14

VQ

For a residential project to build as of right and the emphasis for the target population would be families. So large units, lots of two bedroom and three bedroom units, a lot of outdoor access and the views because of its waterfront proximity.

00;09;00;17 - 00;09;25;13

DP

Yeah, the site is unbelievable. And you guys really take advantage of just about everything out there. It's a great project. So let's talk about the design. So first let's talk about the building stylistically. So to me it looks a lot like a very contemporary warehouse space, right? So there's lots of glass. It almost appears lantern like in the photos that I saw at dusk. It's beautiful.

00;09;25;16 - 00;09;53;28

VQ

The choice of materials was very specific. The neighborhood has a unique grid orientation to the world, and so it captures the light in the sunrise and sunset, in particular. The brick we chose to be a rough, molded brick with a dark mortar and the metal panel has a mica flake to it that captures the light and changes throughout the day.

So sometimes it looks orange and copper. Sometimes it actually looks bronze toned and it has a chocolate sienna undertones to it.

00;09;53;28 - 00;10;05;23

DP

I noticed that in the photographs that the metal definitely takes on a bunch of different colors. So let's back up a little bit. Let's talk about the project restrictions, zoning, any historical requirements for you guys?

00;10;05;26 - 00;10;56;16

VQ

So the site isn't within a landmark district, but as our office really emphasizes context in our practice. So even when there's not those kind of historical restrictions, we like to start there and say, what does it want to be? And so we actually decided early on that we would adopt the one story podium and also set back sooner than we actually needed to.

First, to take a cue from that one story warehouse context, but also how that kind of massing relates to the street and the experience of the street. It increases the light and air and allows for breezes to blow through. It also allows for multiple outdoor terracing to happen. So those units that aren't particularly high and don't have the same views can step out onto your terrace and see the water.

And so really maximizes the value and effectiveness and the quality of those spaces.

00;10;56;19 - 00;11;05;22

DP

So let's talk a little bit about the building and plans. I'm assuming it's along because the lots a long rectangle, the building matches that although it steps back.

00;11;05;24 - 00;11;47;08

VQ

It steps back immediately after the first story. The first story is about 17 feet in height. And so there are some very high ceiling experiences there, ranging from 12 to 14 foot ceilings within the amenities alone. And that also gave us the room to deal with some of the flood constraints as well. Being that the site is adjacent to the East River the predicted flood zones right now are anywhere from 5 to 6 feet above grade. So that was a challenge and a constraint early on where we had to coordinate. We certainly decided we weren't going to excavate because of the high water table. So some of the functions that you would put in the cellar, we put a grade, but we often had to elevate the critical services six feet above where you normally would place them.

00;11;47;10 - 00;11;54;05

DP

So I'm curious, when you're digging that close to the water, do you get a lot of water, a lot of groundwater coming in when you're creating your foundations?

00;11;54;05 - 00;12;22;21

VQ

Yes, you do. Yes. Early on there was a lot of pile driving very deep anywhere from I would say 30 or 40 feet down. And those piles were linked up with large caps, pile caps and then mat foundations at the towers. The slab itself, because of, you know, you have to think more like a boat or a bathtub.

The slab itself was anywhere from 24 inches to 18 inches thick at various points throughout it. And it has to resist uplift.

00;12;22;23 - 00;12;28;07

DP

That's really interesting. So when you're driving piles and there's a lot of bedrock, how do you do that?

00;12;28;10 - 00;12;47;14

VQ

The nature of the historic waterfront is often landfill, so a lot of it is just trash or sediment over 200 years people just dump things in the river and it created a new shoreline, which was often the case, as you see in lower Manhattan as well. So we knew that we were going to have to go deep to hit rock.

00;12;47;20 - 00;12;50;29

DP

So you're driving the piles then 25 or 30 feet.

00;12;50;29 - 00;12;51;18

VQ

Exactly.

00;12;51;18 - 00;12;52;09

DP

I got it.

00;12;52;09 - 00;13;48;10

VQ

Yeah. And another challenge relating to the waterfront edge is we had to deal with actually coordinate with a marine architect because the edge condition was failing and we needed to remediate it. So we coordinated a new driving a new sheet edge along the shore to create that. The site actually is interesting in that it has a natural cove condition that other areas along the waterfront don't.

And so we recreated that in the remediation. But we also worked with the landscape architect to create this. We're obligated by zoning that create a setback for public access on the site. So they really leaned into that curved cove condition that's set back and stepped it down to the water gradually from grade and incorporated eco concrete blocks that have various pockets that allow kind of tide pool action to happen.

And so we thought about breaking down the shoreline a little bit and not just a hard edge.

00;13;48;12 - 00;13;57;21

DP

It sounds really interesting. I mean, when somebody owns a piece of property like that and it's really sitting on debris, in many cases, it's kind of unusual.

00;13;57;24 - 00;14;34;06

VQ

I mean, we tried to find opportunities to maximize the value of the site. With the two tower strategy. We put lots of valuable floor area up high and took advantage of the views. We made double the amount of corner units that you could have by having a two towers. We also separated them over 100 feet apart so that the West Tower really gets out there in front of other buildings that it's alongside.

The East Tower is set back for the east to kind of get around other buildings that could obscure it. And we were actually surprised at how good the views are as it was being built. We knew it was going to be good, but it actually turned out to be better than we anticipated.

00;14;34;09 - 00;14;41;08

DP

It's really beautiful about the design as the corners are opened up then to become porches, right? Terraces, is that correct?

00;14;41;10 - 00;15;04;06

VQ

That's right. This is part of that is a response to some zoning constraints is at a certain height you also had to step back in multiple directions. And one of the things that we like to do is incorporate our balconies into the building facade and not just look like appendages. So we really took advantage of that setback rule and created these covered protected balconies.

Also, it's quite windy, so that coverage helps screen it a little bit.

00;15;04;08 - 00;15;08;14

DP

So an open terrace meets the setback requirements then?

00;15;08;21 - 00;15;09;04

VQ

Yes.

00;15;09;07 - 00;15;13;25

DP

Wow, that's really interesting. So did you guys max out the building height then?

00;15;14;01 - 00;15;36;14

VQ

Yes, we had a R six zoning. We were adjacent to R eight. So there's some taller buildings in the surrounding area. But we did try to sort of maximize it. Part of also with the flood zoning, when you have extreme water table situation, you are allowed to increase up to a certain height. So we were able to utilize the various zoning restrictions to our benefit.

00;15;36;17 - 00;15;39;19

DP

So how long did the building review take with the city?

00;15;39;26 - 00;15;57;14

VQ

Well, certainly just even the public park portion we started in 2008. It probably took a year and a half to two years alone. At the same time, we were overlapping with our design and documentation, so it probably took another two years to really finish all the documentation.

00;15;57;17 - 00;16;09;00

DP

So let's talk a little bit more about the parameters for the building materials and the use of masonry, which from what I can tell from the photos is at the base and then the circulation tower, is that correct?

00;16;09;02 - 00;17;40;06

VQ

The circulation towers are actually stucco with a color to match the metal panel facade. They were really thought of as almost like a concrete massing for the podium. We selected a Glen-Gery Brick that was a molded modular brick. It has orange undertones and some brown tones as well along its finish, and it's a bit city, and we specifically selected it for its character.

It has texture, it catches the light in an interesting way. It's a very practical brick. And so we tried to think about just in the same way that we thought about the rest of the massing and even some of the interior design elements is to marry a practical industrial esthetic that was indigenous to the neighborhood, but also elevated and make it a bit of a luxurious esthetic as well as a hybrid.

So we selected the brick, we selected a dark mortar and did simple moves with the design in terms of let the program and the adjacencies define where those openings wanted to be, because again, 500 feet, we weren't over doing the modulation of that. We really wanted it to say this is where the windows want to be based off of the function of the plan.

And when we knew where those openings would be, we also decided upon simple detailing, corbelling of 1 to 2 inches stack stretcher, bond patterns, soldier brick patterns, which would have been indicative of the kind of twenties, thirties or earlier warehouse context. You know, again, just trying to tie it back to what would have been if it had been built 100 years ago.

00;17;40;08 - 00;17;50;25

DP

Well, I noticed there's a really pretty detail where you're setting the masonry back from the facade to create a reveal for the headers and for some of these openings.

00;17;50;28 - 00;18;03;17

VQ

Yes. And it creates a lot of interplay of light and shadow along the facade. And that was always thought about, you know, how do you deal with such a long facade that would have a lot of opacity to it, but create interest in that opacity.

00;18;03;19 - 00;18;05;17

DP

So did you guys draw the building in BIM?

00;18;05;17 - 00;18;06;17

VQ

Yes.

00;18;06;24 - 00;18;07;29

DP

You guys work in Revit?

00;18;08;04 - 00;18;10;12

VQ

Yeah, we're predominantly a Revit office.

00;18;10;14 - 00;18;19;08

DP

So the studies that you did initially, did you guys draw the whole building in 3D and then show the clients and so they got to see the model? Or did you guys build a physical model too?

00;18;19;10 - 00;18;43;16

VQ

We always start with the Revit process because it has its advantages, sort of quick moves and early viewing studies as well as planning. We did some early models, for the sales we did a full scale model of the whole building as well as the interiors. There's actually a drawer that pulls out of the base of the model and you can see all of the amenities articulated, which is incredible.

00;18;43;18 - 00;18;51;25

DP

Again, I'm curious how large of a set does a project like this create? How many pages just for architecturals?

00;18;51;27 - 00;19;11;26

VQ

That was always a challenge for the documentation was the East West Towers had their own articulations. Between the architectural division and the supporting engineering divisions, we had four volumes of documents just on drawings alone, and I want to say the architectural volume was easily 100 sheets or more unto itself.

00;19;11;28 - 00;19;24;27

DP

Another detail I really like is the exterior facade. So you made the piers and to some extent the floor slabs as they’re exposed on the exterior. It's not really a slab, it looks like steel. It's a really pretty detail.

00;19;24;29 - 00;19;50;24

VQ

Yeah, it's a simple C channel profile that's in ACM, Aluminum Composite Metal panel, and it's an open range screen. We really worked with our facade consultants and structural to simplify the detail as much as possible and maximize the windows. You know, again, this project, by its site positioning and daylighting it wants big windows. So we wanted to coordinate that with slab covers and the column covers.

00;19;50;26 - 00;20;01;15

DP

So could you give me more of an idea of how that open rain screen works? I mean, when I'm looking at the exterior photographs does not look like a rain screen at all. I mean, it looks like an enclosed system.

00;20;01;17 - 00;20;35;18

VQ

The profile clips the slab edge and tacked on to a fin that is part of the window wall extrusion. And that sort of stabilizes the top and bottom relationship and sets the datum for every floor and at every joints we leave it open behind that paneled system is a mineral wall assembly and waterproofing behind that and at the open joints, we coordinated with the shops to return the finish and bend, partly to stiffen the profile, but also finish it off and create a sense of closure.

00;20;35;20 - 00;20;40;20

DP

And what would be the advantage of doing a rain screen versus doing a closed system there?

00;20;40;22 - 00;20;56;05

VQ

It was more practical from an installation and sequencing standpoint and also just maintenance, you know, tall buildings, having to deal with caulking and repairing it later. It's a challenge and you have to think about that for clients’ maintenance. You know, it's a real concern.

00;20;56;07 - 00;21;32;06

DP

Yeah. I'm just getting myself familiar with rain screens. I'm behind residential work and we did a rain screen for my most recent home in New York State and was a real education. It's such an interesting system and I would say I think I tested on it for some CE units that I took maybe a couple of years ago and I thought, Wow, this is a really interesting idea where the facade is actually wide open in some ways and water's allowed just kind of move through it, dry back out again.

You're eliminating a lot of challenges long term by using rain screens.

00;21;32;08 - 00;22;01;14

VQ

I actually have an extensive experience from my school construction authority days of working on rain screens that we often would take existing schools that are 100 year old buildings that were solid wall assemblies, and we found water infiltration. We would take back the finish to the back up and create narrow cavity drainage plains with brick or precast or GFRC elements.

It's definitely in my wheelhouse to work in that context.

00;22;01;17 - 00;22;19;29

DP

It makes perfect sense to allow a wall to dry out rather than capture water behind the facades. All right. But it took us hundreds of years to figure this out. Very interesting. So you guys drew the building in BIM. You have the 3D model. How long have you guys been working in Revit?

00;22;20;01 - 00;22;22;00

VQ

15 to 20 years at least.

00;22;22;03 - 00;22;34;21

DP

Again, I'm kind of curious as an offshoot to this discussion. When you hire people, do you hire people who do not know how to use Revit? Maybe they've used Micro Station or they use ArchiCAD or AutoCAD and then you train them.

00;22;34;28 - 00;23;20;13

VQ

It's ever more common for them to have experiences these days. I actually didn't know Revit when I started, and that was a learning experience for me. You know, it has its pros and cons, you know, if you're an old school CAD person, but I value its ability to, you know, you move a wall, it moves everywhere. You don't have to constantly track that element.

And also when we're doing design options for large complicated projects, thinking about, well, what if the window appears or this dimension or that dimension, we can iterate and quickly deploy changes, you know, especially this day and age where you're dealing with value engineering, they come back with bids, you say, it's got to come out of somewhere. It's an important tool to be able to pivot and retool the design, adapt the design to accommodate these requirements.

00;23;20;15 - 00;24;10;27

DP

It's a really good point for those of you who don't know what BIM is, it's building information modeling, so you're giving lots of information up front to building parts like walls and plan, for example. And initially, at least in my experience, it takes a lot longer to draw something in the beginning, but you've got all that information in there.

So Vicente is explaining that what happens is when you need to make a change, the change is really quick because you're just changing one thing out of a series of pieces of information that you've already kind of filled in. So BIM has really changed the business over the last 15, 20 years. So do you guys learn anything interesting through the design and construction process? Maybe something you'd never dealt with before in terms of details or dealing with the client or the?

00;24;10;27 - 00;25;39;01

VQ

GC Well, certainly that flood design is evolving. We came up with some strategies that even the rules have changed since we started this project. So it's constantly evolving target and some of the forecasted flood elevations have changed across time. So that's something that's an ever evolving discipline of knowledge and thinking about active systems versus passive systems. You know, this building relies on a mixture of passive and active systems, some that the building is set up or either elevated spaces or the wall assemblies set up to resist water, the force of water in other elements, it's relying on staff.

We're trained to deploy solutions that are either barriers or stairs to reduce that access throughout the building. And that's a big challenge with any project that's in a flood zone is egress, space planning services and also mitigating cost. The developer and the clients and the residents ultimately will want to experience these views. But those views are difficult if we're anticipating flooding.

Nobody wants to have windows that are six feet off the ground. We were selective in where we put our efforts and said these areas are going to have the views. We're going to coordinate flood resistant glazing there. The same thought process at the commercial retail and lobby. You know, the places that it mattered. We wanted to maximize the glass. In other areas, we dialed it back down to really use opaque assemblies to articulate the design.

00;25;39;04 - 00;25;42;16

DP

So I mentioned deployable flood barriers. What is that?

00;25;42;18 - 00;26;21;26

VQ

I think of them like Lincoln Logs. Well, there's a range of options out there, but they are often aluminum extrusions that gasket together and stack along channels and they'll go to whatever height that is necessary. They often have back bracing or steel or aluminum sections. Those elements either are built into the facade already or tie back into anchor points that really transfer the loads to the structure.

It's a very complicated interaction and coordination of the design that you want these facade protection elements, the superstructure and waterproofing, you know, it all has to work and it takes a lot of effort.

00;26;21;28 - 00;26;25;28

DP

So what happens to that barrier when there is a flood? Do they break away?

00;26;26;00 - 00;26;27;17

VQ

They resist. They act as a wall.

00;26;27;17 - 00;26;28;21

DP

Resist. Okay. Yeah.

00;26;28;22 - 00;26;39;05

VQ

Normally they're stored in a closet until they're needed. The idea is if you have notice of an impending storm or hurricane, then you would deploy them in advance of the storm.

00;26;39;05 - 00;27;06;01

DP

Thus deployable. Yeah. Interesting. So Vicente, you're a relatively young architect. I say that because at one time I was a young architect and I used to tell my students that you were considered young at 40 or 50. I'm now 55, so please don't be offended by my comment. But based on what you know so far, do you have any words of advice for your younger self or even young architects like yourself just getting started, Not just getting started, but getting started.

00;27;06;08 - 00;27;41;19

VQ

I think curiosity and a willingness to learn a variety of things. Architecture is an interesting creative discipline because there's a lot of rigor and science and technology and law backed up into that knowledge. But it's also trying to solve a problem. You have to really embrace the learning curve of that and learning things that you may not have mastery of, but your organizing, those various constraints and knowledge is into a solution.

And I think that's, if you're enthusiastic and go with it and embrace it, I think you get a lot out of it.

00;27;41;22 - 00;27;57;05

DP

Yeah, I totally agree. I like to tell people architecture is a field where you have to know a lot about a lot. It's as simple as that. So, Vicente, it's been great to speak with you today. Thanks for your time. Where can people go to learn more about Morris Adjmi Architects and yourself?

00;27;57;11 - 00;28;05;26

VQ

You can go to MA.com, our website. You can also check out The Huron Instagram. You can also visit the site. It's a beautiful building.

00;28;06;02 - 00;28;08;18

DP

Yeah, it's a great project. Well, thank you very much, Vicente.

00;28;08;22 - 00;28;12;23

VQ

Thank you.

You May Also Be Interested In

We Can Help With Your Next Project

Discover the latest + greatest in design trends, industry news & pro tips from pros.

For all of your project needs, you’ll find everything you need at a Supply Center.

Let Us Know How We Can Help!

Design Vault Ep. 30 TCS Hall with Kent Suhrbier

ABOUT THE ARCHITECT:

|

Kent Suhrbier is a Principal in Bohlin Cywinski Jackson’s Pittsburgh studio. Kent’s approach to design values evocative environments that maintain a thoughtful sensitivity to the natural environment and the communities they serve. His work ranges from civic facilities and museums to centers for engineering and innovation, corporate headquarters, and university laboratories. The core theme to this diverse experience is his commitment to crafting spaces that define new paradigms, as has been the case on projects like the Frick Environmental Center and Carnegie Mellon University’s ANSYS Hall and TCS Hall. As a designer who cares deeply about promoting a more diverse, talented next generation of designers, he has a continuing role as an Adjunct Professor at Carnegie Mellon University. |

|---|

ABOUT THE PROJECT:

Carnegie Mellon University built TCS Hall, which is a new academic building on Forbes Avenue at the western edge of its campus. The project aimed to allow for future expansion and create connections between the campus and the nearby community.

It was designed to accommodate both private and university users, providing flexible spaces for collaboration while respecting the need for privacy. The finished project, an 88,000 square foot LEED gold certified facility, was done in collaboration with Tata Consultancy Services. The building houses the Institute for Software Research, the Master of Science in Computational Finance Program, the Center for Business Engagement and the TCS Think Tank, all of which promote academic research, innovation and professional development.

The partnered brickwork drew inspiration from the original Horn Postle campus architecture, reflecting the economic significance of brick as a building material in Pittsburgh. This was combined with terracotta and glass to create a balanced, contemporary aesthetic. Various colors and coursing a brick appear across the elevations, such as running bond, stacked and soldier. The brick walls subtly undulate as they mix with flat, dark window bars that dance across the facade.

TRANSCRIPT

00;00;00;03 - 00;00;05;13

Doug Pat (DP)

Let's go inside the vault. The design vault.

00;00;05;16 - 00;00;44;27

Kent Suhrbier (KS)

The one thing that then really influenced the design of the building was meeting a kind of very wide floor plate that could accommodate sort of larger laboratory spaces in addition to lots of perimeter office and workspaces. And so this is an asymmetrical core where we pull everything to one side. We then also cut a big connective series of stairs and interlocking spaces through the center of the building that also gave us some ability to have a relationship between the all the tenants within the building so that they can see each other, experience what's going on with each other, but not be in each other's business.

00;00;44;29 - 00;03;45;00

DP

This is my guest, Kent Suhrbier. I'll share more about him shortly. In this episode from the Design Vault, we highlight Kent's project, TCS Hall at Carnegie Mellon University in Pittsburgh, Pennsylvania. Carnegie Mellon University built TCS Hall, which is a new academic building on Forbes Avenue at the western edge of its campus. The project aimed to allow for future expansion and create connections between the campus and the nearby community.

It was designed to accommodate both private and university users, providing flexible spaces for collaboration while respecting the need for privacy. The finished project, an 88,000 square foot LEED gold certified facility, was done in collaboration with Tata Consultancy Services. The building houses the Institute for Software Research, the Master of Science in Computational Finance Program, the Center for Business Engagement and the TCS Think Tank, all of which promote academic research, innovation and professional development.

The partnered brickwork drew inspiration from the original Horn Postle campus architecture, reflecting the economic significance of brick as a building material in Pittsburgh. This was combined with terracotta and glass to create a balanced, contemporary aesthetic. Various colors and coursing a brick appear across the elevations, such as running bond, stacked and soldier. The brick walls subtly undulate as they mix with flat, dark window bars that dance across the facade.

A cost effective approach was taken to create the rhythmic facade pattern using the logic of binary base code to develop the esthetic modules. Hi, I'm Doug Pat and this is Design Vault. Kent Suhrbier holds a Bachelor of Architecture from Carnegie Mellon University and is a fellow of the AIA. He's also a principal at Bohlin Cywinski Jackson’s Pittsburgh studio.

His work for them includes civic facilities, museums, centers for engineering and innovation, corporate headquarters and university laboratories. The core theme of his diverse experience is his commitment to crafting spaces that define new paradigms, as has been the case on projects like the Frick Environmental Center and Carnegie Mellon Universities ANSYS and TCS halls. His approach to design values, evocative spaces that maintain a thoughtful sensitivity to the natural environment and the communities they serve.

Kent has spent many years teaching the practice of architecture and is deeply committed to mentoring and nurturing the next generation of designers. He's currently an adjunct professor at Carnegie Mellon University. So welcome, Kent. It's nice to have you with us today. So tell us a little bit about balance, a Bohlin Cywinski Jackson studio.

00;03;45;02 - 00;04;30;09

KS

That's a pleasure, Doug. So we're a national practice with studios across the country. Our Pittsburgh studio has been here for little more than 45 years, and it's always been located in the center of downtown Pittsburgh. And similar to kind of all of our groups, works on a blend of typologies in terms of buildings. So we do everything from residential to multifamily.

But at the core of a lot of our work is our university buildings and university projects. And we've been fortunate in the Pittsburgh region to have a very long relationship with Carnegie Mellon that goes back to originally the software engineering Institute and then the Intelligent workplace. And then in more recent years, working on the work with ANSYS Hall and now TCS Hall.

00;04;30;16 - 00;04;36;22

DP

And this is a big firm. So you guys have studios across the United States. Where are they and what's the overall size of the business?

00;04;36;24 - 00;05;04;05

KS

We're not that large. We are about 100 people and we're located in studios in Seattle, San Francisco, Pittsburgh, Philadelphia, and Wilkes-Barre. We started in Pennsylvania. We still have a strong presence in Pennsylvania, but we also, over the years, have created quite a strong studio in Seattle. All the studios develop really about this idea of craft. And so each one kind of has settled in that nature in their place.

00;05;04;07 - 00;05;07;11

DP

So you've been an architect for some time over 30 years, right?

00;05;07;14 - 00;05;09;06

KS

Yes.

00;05;09;08 - 00;05;15;08

DP

Time flies. So tell us a little bit about your experience as an architect. Have you always worked for BCJ?

00;05;15;11 - 00;05;29;06

KS

I worked for BCJ early in my career and then went and had my own practice for a number of years while I was teaching and then had an opportunity to come back to BCJ in the Pittsburgh studio about ten years ago. And we've been at it ever since.

00;05;29;08 - 00;05;32;09

DP

And have you taught anywhere other than Carnegie Mellon?

00;05;32;12 - 00;05;37;18

KS

No. Lots of critiques and reviews, but most of my teaching has been based at CMU.

00;05;37;21 - 00;05;43;01

DP

So let's dig in here and talk about the project. So how did your office get the project?

00;05;43;03 - 00;06;30;02

KS